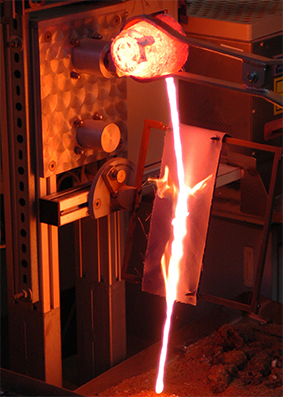

When it comes to working in industrial environments where molten metal is present, ensuring the safety of workers is paramount. This is where molten metal protection garments come into play as a game-changer. These specialized garments are designed to provide a crucial layer of defense against the extreme heat and potential hazards posed by molten metal, offering a lifeline of protection for those working in high-risk settings.

Importance of Molten Metal Protection

Protecting workers from the dangers of molten metal is a paramount concern in industrial environments. The importance of molten metal protection garments cannot be overstated, as they serve as a crucial line of defense against severe injuries and even fatalities. Imagine being exposed to scorching molten metal without the proper protective gear – it’s like entering a battlefield without armor, leaving you vulnerable to the destructive forces at play.

When molten metal comes into contact with unprotected skin, the results can be catastrophic. Severe burns, permanent disfigurement, and even loss of life are all potential outcomes of such exposure. This underscores the critical need for specialized garments that can withstand the extreme heat and provide a shield against molten metal splashes. The right protective gear can make all the difference between a safe work environment and a hazardous one.

Let’s take a small break from our article. You can review BundleTec products and services from the link below.

In industrial settings where molten metal is a constant presence, the risk of accidents is ever-present. Workers face the daily challenge of navigating a high-temperature environment where a single misstep could have devastating consequences. By investing in quality molten metal protection garments, companies not only prioritize the well-being of their employees but also demonstrate a commitment to safety that resonates throughout the organization.

Types of Molten Metal Protection Garments

When it comes to protecting workers from the dangers of molten metal in industrial environments, having the right protective garments is crucial. There are several types of specialized gear designed to shield individuals from the intense heat and potential splashes of molten metal. Let’s explore the different types of molten metal protection garments available:

- Molten Metal Suits: These full-body suits are made from heat-resistant materials and provide comprehensive coverage to protect workers from head to toe.

- Molten Metal Gloves: These gloves are designed to withstand high temperatures and prevent burns or injuries to the hands and fingers when handling molten metal.

- Molten Metal Boots: Specialized boots made from durable materials that offer heat resistance and protection against molten metal splashes, ensuring the safety of workers’ feet.

- Face Shields and Helmets: Essential for protecting the face and head from molten metal splashes and heat, these items are crucial in ensuring complete safety for workers.

Each type of molten metal protection garment serves a specific purpose in safeguarding workers from the inherent risks associated with working around molten metal. Whether it’s the full-body coverage of a molten metal suit or the precision protection of gloves and boots, these garments play a vital role in ensuring the safety and well-being of industrial workers.

Key Features to Look For

When it comes to selecting the right molten metal protection garments, there are several key features to consider that can make a significant difference in ensuring the safety and well-being of workers. Here are some essential aspects to look for:

- Heat Resistance: One of the most crucial features of any protective garment is its ability to withstand high temperatures. Look for materials that offer excellent heat resistance to protect against molten metal splashes and radiant heat.

- Durability: Molten metal environments can be harsh and demanding, so durability is paramount. Choose garments made from robust materials that can withstand the rigors of industrial settings without compromising on protection.

- Ergonomic Design: Comfort and mobility are key factors in ensuring that workers can perform their tasks effectively while staying protected. Seek garments with ergonomic designs that allow for ease of movement and flexibility.

- Compliance with Safety Standards: It is essential to choose garments that meet or exceed industry safety standards to ensure proper protection. Look for certifications and compliance with relevant regulations to guarantee the effectiveness of the protective gear.

Advancements in Protective Technologies

Advancements in protective technologies have revolutionized the field of molten metal protection garments, enhancing the safety and comfort of workers in high-risk environments. These innovations have paved the way for superior protection against molten metal hazards, reducing the risk of injuries and accidents. Let’s delve into some of the key advancements that have transformed the landscape of protective technologies:

- Advanced Heat-Resistant Materials: The development of cutting-edge materials with exceptional heat resistance properties has significantly improved the effectiveness of molten metal protection garments. These materials can withstand extreme temperatures, providing a reliable barrier against molten metal splashes.

- Ergonomic Design Features: Modern protective technologies focus on ergonomic design elements to enhance the comfort and mobility of workers. Garments are now tailored to fit securely and allow for ease of movement, ensuring that workers can perform their tasks efficiently without compromising safety.

- Integrated Cooling Systems: Some innovative protective garments now come equipped with integrated cooling systems that help regulate body temperature in high-heat environments. These systems ensure that workers remain cool and comfortable, even when exposed to intense heat from molten metal.

- Smart Sensor Technology: The integration of smart sensor technology in protective garments enables real-time monitoring of environmental conditions and the wearer’s vital signs. This technological advancement allows for immediate alerts in case of any potential risks or emergencies, enhancing overall safety.

Furthermore, advancements in protective technologies have led to the development of customizable and adaptable garments that cater to the specific needs of different industrial settings. These tailored solutions offer enhanced protection and versatility, ensuring that workers are equipped with the most effective gear for their unique working conditions. Overall, the continuous innovation in protective technologies underscores the commitment to prioritizing worker safety and well-being in environments where molten metal hazards pose significant risks.