Pulling screw jacks are the muscle behind the scenes when it comes to immobilizing welded parts in steel structures. Unlike their lifting counterparts, pulling screw jacks exert a pulling or clamping force, perfect for ensuring tight and secure connections during the welding process. Here’s how these jacks play a crucial role in steel structure fabrication:

The Clamping Powerhouse:

- Pulling screw jacks provide a controlled and powerful pulling force that draws components together. This force helps to close any gaps between welded parts, creating a tight and secure joint essential for a strong and lasting weld.

Benefits of Using Pulling Screw Jacks for Welding:

- Improved Weld Quality: By eliminating gaps and ensuring proper alignment, pulling screw jacks contribute to higher quality welds. This translates into stronger and more reliable connections in the final structure.

- Enhanced Efficiency: Screw jacks offer precise control over the clamping force, allowing for faster and more efficient weld preparation compared to traditional methods like clamps or wedges.

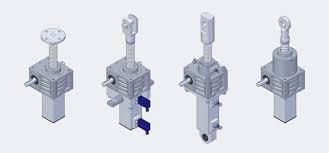

- Versatility for Various Applications: Pulling screw jacks come in a variety of sizes and capacities, making them suitable for a wide range of steel structures and weld sizes.

- Safety Advantages: Screw jacks provide a safe and controlled method for clamping welded parts, reducing the risk of worker injury compared to using hammers or forceful manual manipulation.

Considerations for Utilizing Pulling Screw Jacks:

- Matching Capacity to Clamping Force: Selecting a screw jack with sufficient capacity is crucial to ensure it can generate the necessary pulling force for a secure weld. Factors like weld size and material thickness influence the required force.

- Anchor Point Selection: Choose secure anchor points for the screw jack to ensure it can effectively pull the components together. The anchor points need to be strong enough to withstand the pulling force without compromising the structure.

- Accessibility and Maneuverability: Consider the workspace and accessibility when choosing a screw jack. Some models may be more compact or offer features like swivel bases for better maneuverability in tight spaces.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Applications Beyond Welding:

While excelling in the welding realm, pulling screw jacks have applications beyond steel structure fabrication. They can be used in various industrial settings for tasks like:

- Machine Alignment: Precise positioning and alignment of machinery components during installation or maintenance.

- Fixture Clamping: Securely holding workpieces in place during machining, assembly, or testing procedures.

- Tensioning Applications: Applying controlled tension to cables, wires, or ropes in various industrial processes.

Conclusion:

Pulling screw jacks are a valuable asset for steel structure fabrication, offering a safe, efficient, and powerful method for immobilizing welded parts. Their versatility and range of applications make them a go-to tool for various industrial tasks requiring precise clamping and controlled pulling force.