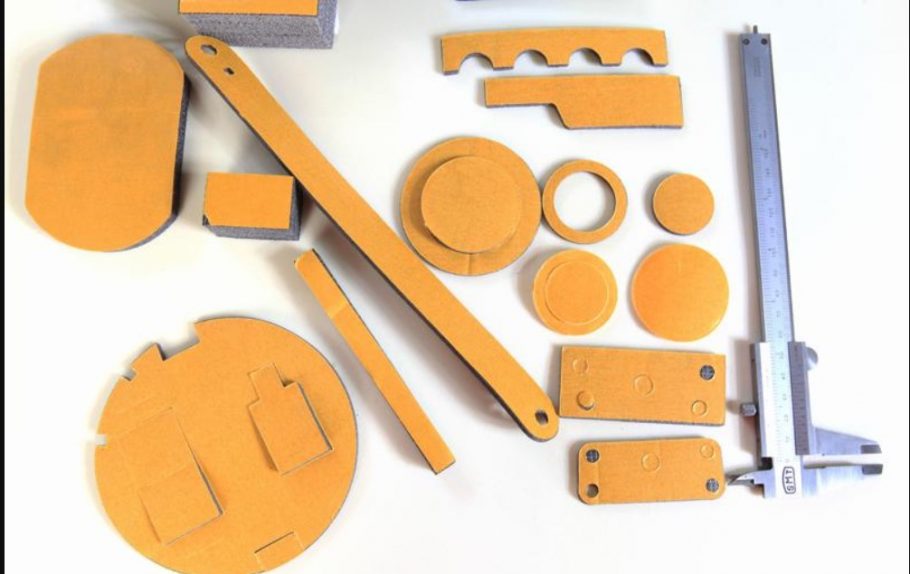

Physically cross-linked polyethylene foam is a remarkable material that offers a plethora of surprising benefits across various industries. From its lightweight and durable properties to excellent shock absorption and resistance to water and chemicals, this foam stands out as a versatile solution for a wide range of applications.

When it comes to lightweight and durability, physically cross-linked polyethylene foam truly shines. Its lightweight nature makes it easy to handle while still maintaining exceptional strength and durability. This unique combination makes it a top choice for applications where both sturdiness and ease of use are essential.

One of the standout features of physically cross-linked polyethylene foam is its excellent shock absorption capabilities. Whether it’s used in sports equipment to cushion impacts or in packaging to protect fragile items during transit, this foam excels at dampening vibrations and reducing the effects of sudden shocks.

Let’s take a small break from our article. You can review Durfoam products and services from the link below.

Moreover, the water and chemical resistance of physically cross-linked polyethylene foam make it a reliable option for environments where exposure to moisture or corrosive substances is a concern. This resistance ensures that the foam remains intact and effective even in challenging conditions, adding to its overall versatility and longevity.

Lightweight and Durable Properties

When it comes to physically cross-linked polyethylene foam, its lightweight and durable properties stand out as remarkable features that make it a preferred choice in various industries. The combination of being lightweight and durable makes this foam an excellent material for a wide range of applications, offering the perfect balance between strength and ease of handling.

Imagine a material that feels light as a feather but is tough enough to withstand the harshest conditions without losing its shape or integrity. That’s the magic of physically cross-linked polyethylene foam. Whether it’s used in packaging, insulation, sports equipment, or any other application, this foam excels in providing the necessary strength while being easy to work with due to its lightweight nature.

Moreover, the durability of physically cross-linked polyethylene foam ensures that it can endure daily wear and tear, repeated impacts, and rough handling without breaking down. This resilience is a valuable asset in industries where robust materials are essential for long-term performance and cost-effectiveness.

Let’s not forget the convenience that comes with using a material that is both lightweight and durable. Handling and transporting products made with physically cross-linked polyethylene foam become more manageable and efficient due to its lightweight properties. This not only saves time and effort but also reduces the overall logistics costs associated with heavy and bulky materials.

Excellent Shock Absorption

When it comes to shock absorption, physically cross-linked polyethylene foam stands out as a top performer in the material world. Its unique structure allows it to efficiently absorb and disperse energy, providing unparalleled protection against impacts and vibrations. Imagine it as a shield that embraces your valuable products, safeguarding them from the unpredictable forces of the environment.

The secret lies in the foam’s ability to compress and rebound, absorbing the shock waves like a spring, preventing them from reaching the delicate contents within. This feature makes it an ideal choice for packaging fragile items, ensuring they reach their destination unscathed. Whether it’s delicate electronic components or precious glassware, this foam acts as a reliable bodyguard, ready to take on any unexpected jolts along the way.

Moreover, the exceptional shock absorption properties of physically cross-linked polyethylene foam extend beyond packaging. In sports equipment, this material plays a crucial role in enhancing performance and safety. From helmet liners that cushion against impacts to padding in protective gear that shields athletes during intense activities, the foam’s ability to absorb shocks is truly remarkable.

Picture a marathon runner wearing shoes with soles made of this foam, effortlessly gliding over uneven terrain while the foam absorbs the impact of each step, reducing the strain on their joints. It’s like having a personal shock absorber, allowing them to push their limits without fear of injury. The versatility of physically cross-linked polyethylene foam in providing shock absorption solutions knows no bounds, making it an indispensable asset across various industries.

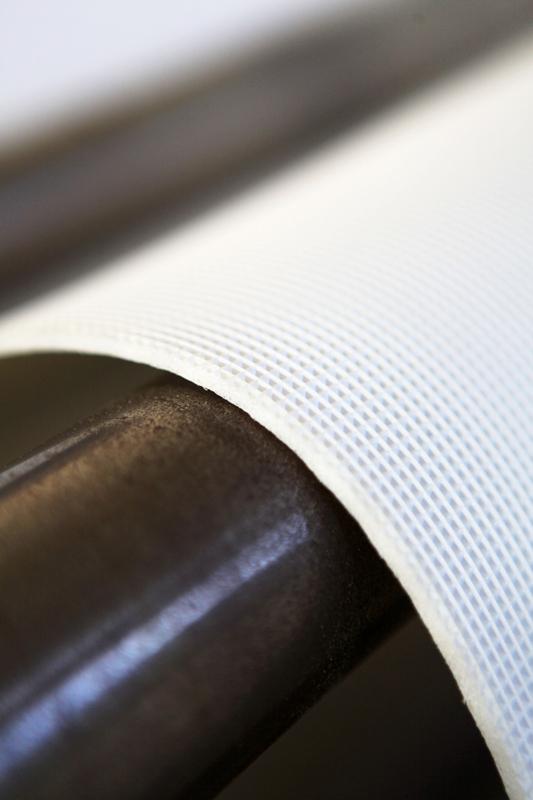

Water and Chemical Resistance

This type of foam exhibits excellent resistance to water and chemicals, making it suitable for use in environments where exposure to moisture or corrosive substances is a concern. Physically cross-linked polyethylene foam creates a protective barrier that shields against water infiltration, ensuring the integrity of the material it encases. Whether used in packaging for sensitive electronics or as insulation in damp environments, this foam’s resistance to water is a valuable asset.

Moreover, the chemical resistance of physically cross-linked polyethylene foam adds another layer of versatility to its applications. It can withstand exposure to various chemicals without degrading, maintaining its structural integrity over time. This feature is particularly advantageous in industries where contact with corrosive substances is common, such as the automotive and manufacturing sectors.

When compared to traditional foam materials, the water and chemical resistance of physically cross-linked polyethylene foam sets it apart as a reliable choice for demanding environments. Its ability to repel moisture and resist chemical degradation ensures long-lasting performance, providing peace of mind to manufacturers and end-users alike.